PLC Programming Best Practices

Proven methods for maintainable PLC programs: naming conventions, structuring, and error handling with Siemens TIA Portal following IEC 61131-3.

1.Introduction

PLC programming is more than just stringing logic blocks together. In over 10 years as an automation engineer, I've seen countless PLC projects – many with typical problems:

- Unreadable variable names like

M0.0,DB1.DBX0.0, or%MW100 - Inconsistent programming language mix – LAD, FBD, STL, and SCL wildly mixed in the same project

- Missing documentation – the original programmer left the company long ago

In this article, I share the most important best practices for maintainable PLC programs with Siemens TIA Portal.

Target Audience

This article is aimed at PLC programmers with basic knowledge of TIA Portal. For beginners, I recommend first taking an IEC 61131-3 fundamentals course.

2.Why Best Practices in PLC Programming?

2.1.The Problem: Legacy Code

Typical scenario from my practice:

A machine builder calls: "Our plant is down. Can you help?"

On-site disillusionment:

- Variable names like

M0.0,DB1.DBX0.0,%MW100– nobody knows what they mean - LAD, FBD, STL, and SCL wildly mixed in the same project

- No comments, no structure

- Original programmer left the company years ago

Troubleshooting takes unnecessarily long because nobody can navigate the code.

2.2.The Solution: Professional Programming

Structured, maintainable PLC programs bring clear advantages:

- Faster troubleshooting through descriptive variable names

- Shorter onboarding time for new programmers

- Fewer machine downtimes through better error handling

3.Best Practice 1: Consistently Use IEC 61131-3 Standards

IEC 61131-3 is the international standard for PLC programming and mandatory for CE-certified machines.

3.1.The 5 Programming Languages Overview

| Language | Use Case | Advantages | Disadvantages |

|---|---|---|---|

| SCL (Structured Control Language) | Complex algorithms, calculations | Clear, readable, type-safe | Not for hard real-time |

| LAD (Ladder Diagram) | Simple logic, electrician-friendly | Intuitive for electricians | Unclear with > 50 rungs |

| FBD (Function Block Diagram) | Control, data flow logic | Graphically understandable | Hard to maintain with large programs |

| ST (Structured Text) | Like SCL, IEC 61131-3 standard | Compact, fast | Steep learning curve |

| SFC (Sequential Function Chart) | Sequential control (GRAFCET) | State machines visualized | Overhead for simple logic |

My Recommendation

Use SCL/ST for 80% of code (logic, calculations, sequential control) and LAD only for simple interlocks (e.g., E-STOP logic). FBD for control loops, SFC for complex state machines.

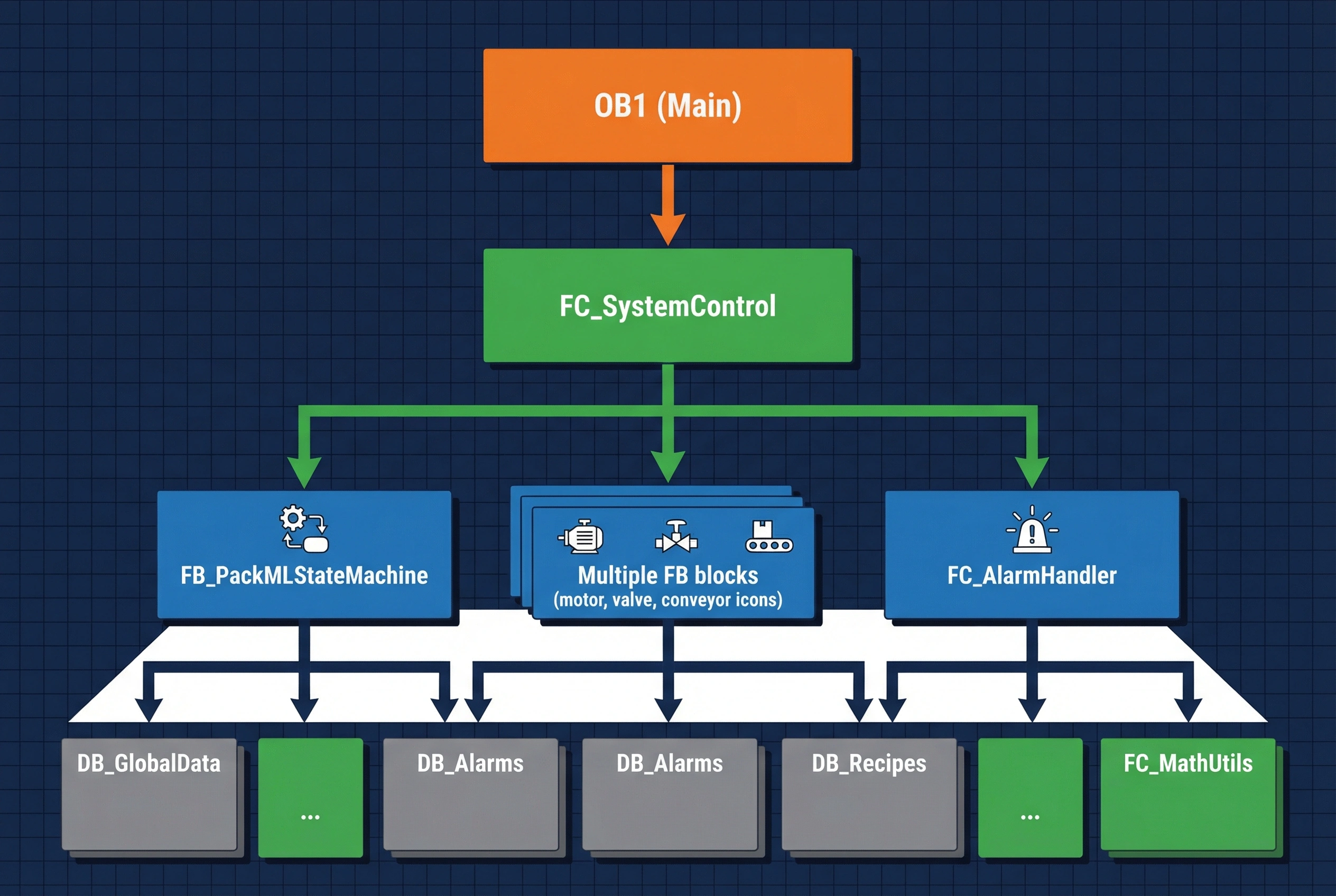

3.2.Structured Programming: The Pyramid

OB1 (Main)

└── FC_SystemControl (Operating modes)

├── FB_PackMLStateMachine (Sequential control)

│ ├── FB_MotorControl (Component)

│ ├── FB_ValveControl (Component)

│ └── FB_ConveyorControl (Component)

└── FC_AlarmHandler (Utility)

Rule: Each level has exactly ONE clear responsibility.

4.Best Practice 2: Establish Naming Conventions

4.1.The Problem: Variable Name Chaos

Negative example (from practice):

// ❌ BAD

M0.0 // What is this?

DB1.DBX0.0 // Which motor?

%MW100 // Temperature? Pressure?

Positive example:

// ✅ GOOD

bMotorPumpMainRun : BOOL; // Main pump motor running

iTemperatureTank1 : INT; // Tank 1 temperature in °C

rPressureSetpoint : REAL; // Pressure setpoint in bar

4.2.Standardized Prefixes (Hungarian Notation)

| Prefix | Data Type | Example |

|---|---|---|

b | BOOL | bMotorRun, bAlarmActive |

i | INT | iCounter, iTemperature |

r | REAL | rSpeed, rPressure |

s | STRING | sAlarmText, sRecipeName |

dt | DATE_TIME | dtStartTime, dtLastMaintenance |

t | TIME | tDelayStart, tCycleTime |

udi | UDINT | udiPartCounter, udiTotalProduction |

4.3.Inputs/Outputs with Prefix

// Inputs: ix (Input X)

ixMotorFeedbackRun : BOOL AT %I0.0; // "x" = Bool

iwTemperatureSensor : WORD AT %IW0; // "w" = Word

// Outputs: qx (Output X)

qxMotorStart : BOOL AT %Q0.0;

qwValvePosition : WORD AT %QW0;

Consistency is king: Decide on ONE convention with your team and document it.

Tooling

Siemens TIA Portal v18+ offers Code Quality Check that automatically checks naming conventions.

5.Best Practice 3: Use Function Blocks vs. Functions Correctly

5.1.Function Blocks (FB) - Stateful

When to use?

- Components with state (motor, valve, conveyor)

- Alarm handlers

- State machines

Example: Motor Control

FUNCTION_BLOCK FB_MotorControl

VAR_INPUT

bStart : BOOL; // Start command

bStop : BOOL; // Stop command

bFeedback : BOOL; // Motor running feedback

END_VAR

VAR_OUTPUT

qxStart : BOOL; // Motor start output

bRunning : BOOL; // Status: Motor running

bAlarm : BOOL; // Fault active

END_VAR

VAR

tDelayStart : TON; // Start delay

tTimeoutFeedback : TON; // Feedback timeout

bAlarmLatched : BOOL; // Latched fault

END_VAR

// Program logic here...

END_FUNCTION_BLOCK

Call:

// In OB1 or FC

dbMotorPumpMain(

bStart := bSystemRun AND NOT bEmergencyStop,

bStop := bSystemStop OR bEmergencyStop,

bFeedback := ixMotorPumpMainFeedback

);

qxMotorPumpMainStart := dbMotorPumpMain.qxStart;

5.2.Functions (FC) - Stateless

When to use?

- Calculations without state

- Scaling

- Mathematical operations

- Utility functions

Example: Temperature Scaling

FUNCTION FC_ScaleTemperature : REAL

VAR_INPUT

iwRawValue : INT; // Raw sensor value (0-27648)

rMinTemp : REAL; // Minimum temperature (e.g., -50°C)

rMaxTemp : REAL; // Maximum temperature (e.g., +150°C)

END_VAR

// Scaling 0-27648 → rMinTemp to rMaxTemp

FC_ScaleTemperature := rMinTemp +

(REAL#iwRawValue / 27648.0) * (rMaxTemp - rMinTemp);

END_FUNCTION

Call:

rTemperatureTank1 := FC_ScaleTemperature(

iwRawValue := iwTempSensor1,

rMinTemp := -50.0,

rMaxTemp := 150.0

);

Rule of Thumb

Does it have state (memory between calls)? → FB Is it a calculation or utility function? → FC

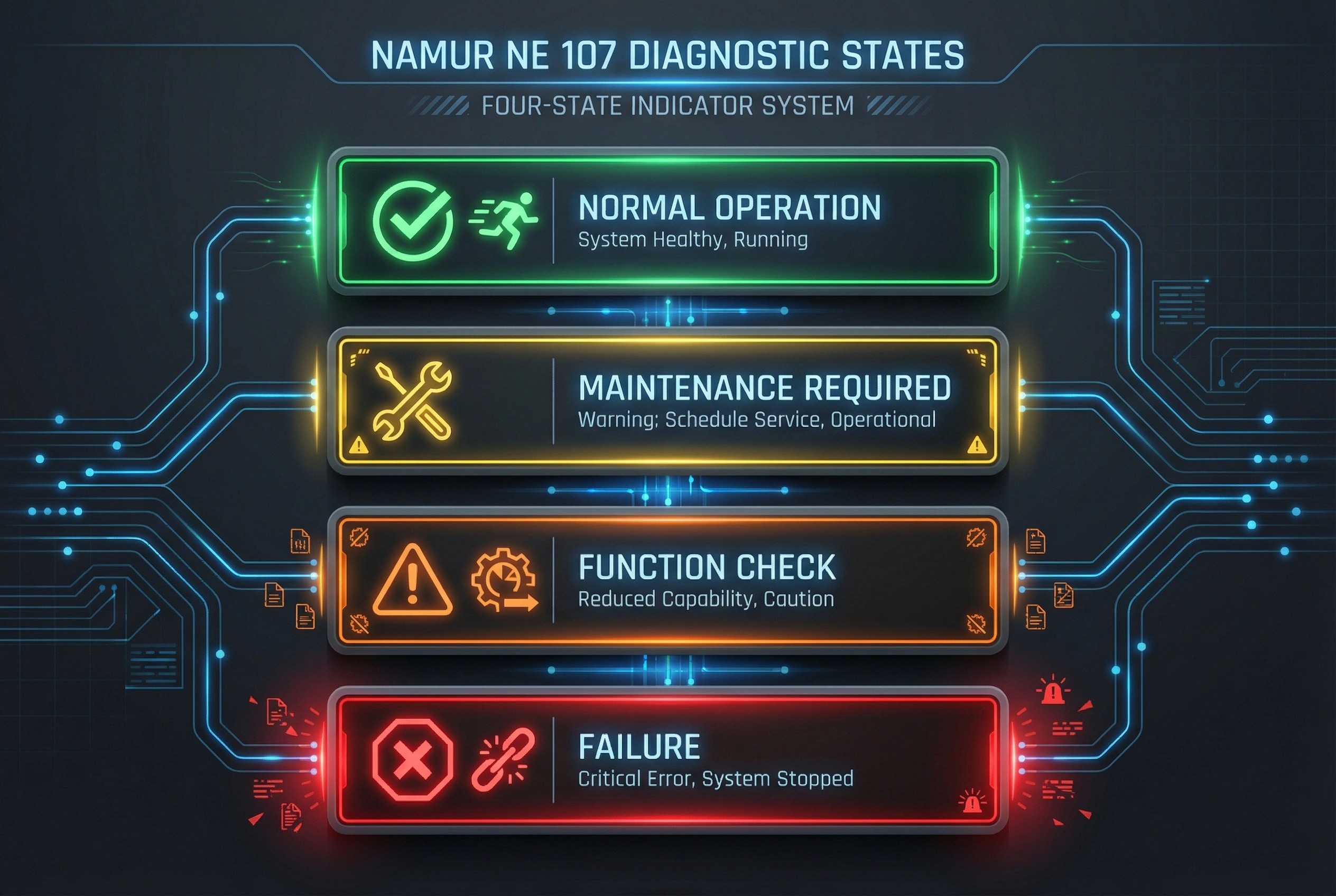

6.Best Practice 4: Error Handling According to NAMUR NE 107

NAMUR NE 107 is the industry standard for self-monitoring and diagnostics in process automation. In mechanical engineering, it has also become established.

6.1.The 4 States

6.2.Implementation with FB_AlarmHandler

FUNCTION_BLOCK FB_AlarmHandler

VAR_INPUT

bTrigger : BOOL; // Alarm trigger

eAlarmLevel : INT; // 1=Info, 2=Warning, 3=Error, 4=Critical

sAlarmText : STRING[80]; // Alarm text

END_VAR

VAR_OUTPUT

bAlarmActive : BOOL; // Alarm is active

bAckRequired : BOOL; // Acknowledgment required

END_VAR

VAR

bAlarmLatched : BOOL; // Latched alarm

dtTimestamp : DATE_TIME; // Alarm timestamp

END_VAR

// Logic: Latch alarm, set timestamp, acknowledge if needed

IF bTrigger AND NOT bAlarmLatched THEN

bAlarmLatched := TRUE;

dtTimestamp := CURRENT_TIMESTAMP();

bAlarmActive := TRUE;

// Logging to HMI/SCADA

// ...

END_IF;

bAckRequired := bAlarmLatched AND eAlarmLevel >= 3;

END_FUNCTION_BLOCK

Best Practice: A central alarm manager collects all alarms and communicates them bundled to the HMI.

Important

Each alarm needs a unique ID (e.g., ALM-001) and a description in documentation. This is mandatory for FDA-regulated systems.

7.Best Practice 5: Version Control with Git

Yes, Git works for PLC code too! Since TIA Portal v18, integration has become significantly easier.

7.1.Setup: TIA Portal with Git

1. Activate Multiuser Engineering

TIA Portal → Project → Properties → Multiuser Engineering → Activate

2. Save project in Git-friendly format

# .gitignore for TIA Portal

*.ap18

*.zap18

__OPNB*

*.bak

3. Initialize Git repository

git init

git add .

git commit -m "Initial commit: TIA Portal project setup"

7.2.Branching Strategy for PLC Projects

main (Production code)

├── develop (Development)

│ ├── feature/motor-control-update

│ ├── feature/add-safety-logic

│ └── bugfix/alarm-text-typo

└── hotfix/critical-emergency-stop-bug

Workflow:

- Create feature branch:

git checkout -b feature/new-conveyor-logic - Commit changes:

git commit -m "Add conveyor start delay 2s" - Create pull request (GitHub, GitLab)

- Code review by second programmer

- Merge into

develop - Testing on development PLC

- Release branch →

main

Advantages

- Team collaboration without data loss

- Historical versions retrievable anytime

- Parallel work on different features

- Automatic backups (GitHub, GitLab Cloud)

8.Best Practice 6: Comments and Documentation

8.1.Code Comments: The 3-Line Rule

Bad:

// ❌ Obvious, adds nothing

bMotorRun := TRUE; // Start motor

Good:

// ✅ Explains WHY, not WHAT

// 2s delay due to pressure build-up in hydraulic circuit

// (See requirement REQ-HYD-012)

tDelayStart(IN := bStartRequest, PT := T#2S);

qxMotorStart := tDelayStart.Q;

8.2.Documentation Standards

For each FB/FC:

(*

Name: FB_MotorControl

Version: 1.2.0

Author: David Prybisch

Date: 2025-11-22

Description:

Standardized motor control with start delay,

feedback monitoring and fault latching.

Change History:

v1.2.0 - 2025-11-22 - Added timeout monitoring

v1.1.0 - 2025-10-15 - NAMUR alarm integration

v1.0.0 - 2025-09-01 - Initial version

*)

FUNCTION_BLOCK FB_MotorControl

// ...

END_FUNCTION_BLOCK

UML Diagrams for System Architecture:

Use tools like PlantUML or Microsoft Visio to visualize overall architecture.

9.Best Practice 7: Testing and Simulation

9.1.Simulation with PLCSIM

Siemens PLCSIM Advanced allows testing PLC programs without physical hardware:

Workflow:

- Develop PLC program in TIA Portal

- Start PLCSIM Advanced and load project

- Set and check variables via watch table

- Systematically test sequential controls

Advantages:

- Detect errors early – in the office instead of at the customer's site

- New programmers can test safely

- Validate changes before commissioning

Tip

Use watch tables in TIA Portal to systematically force inputs and outputs and check program behavior.

10.Best Practice 8: Performance Optimization

10.1.Keep CPU Utilization in Check

Common performance killers:

- Too many timers/counters → Use arrays instead of individual variables

- String operations in real-time cycles → Move to lower-priority tasks

- Complex calculations in OB1 → Use cyclic interrupts (OB35)

Example: Array-based Timer Management

// ❌ BAD: 100 individual timers

VAR

tMotor1 : TON;

tMotor2 : TON;

// ... 98 more timers

END_VAR

// ✅ GOOD: Array of timers

VAR

atMotorTimers : ARRAY[1..100] OF TON;

END_VAR

// Call in loop

FOR i := 1 TO 100 DO

atMotorTimers[i](IN := abMotorStart[i], PT := T#2S);

aqxMotorStart[i] := atMotorTimers[i].Q;

END_FOR;

10.2.Memory Optimization with Multi-Instances

Problem: Each FB instance consumes its own DB (instance DB).

Solution: Multi-instances for recurring blocks.

// FB_ConveyorLine contains 10x FB_MotorControl as multi-instance

FUNCTION_BLOCK FB_ConveyorLine

VAR

Motor1 : FB_MotorControl; // Multi-instance

Motor2 : FB_MotorControl;

// ...

END_VAR

// Create only ONE instance of FB_ConveyorLine

dbConveyorLine : FB_ConveyorLine; // Saves 90% memory vs. 10 separate FBs

11.Conclusion: Professional PLC Programming Pays Off

The investment in structured, maintainable PLC programs pays off multiple times:

- Faster troubleshooting through descriptive variable names and clear structure

- Shorter onboarding time for new programmers

- Fewer machine downtimes through better error handling

- Easier maintenance over the entire system lifetime

11.1.Checklist for Your Next PLC Project

- Naming conventions agreed and documented with team

- Hierarchical program structure planned (UML diagram)

- IEC 61131-3 standards followed

- Alarm management according to NAMUR NE 107 implemented

- Git repository set up and

.gitignoreconfigured - Simulation with PLCSIM prepared

- Code review process established

- Documentation (FB header, system architecture) created

Next Step

Start small: Take an existing project and refactor ONE FB according to these best practices. The time investment (2-4 hours) pays off at the next troubleshooting session.

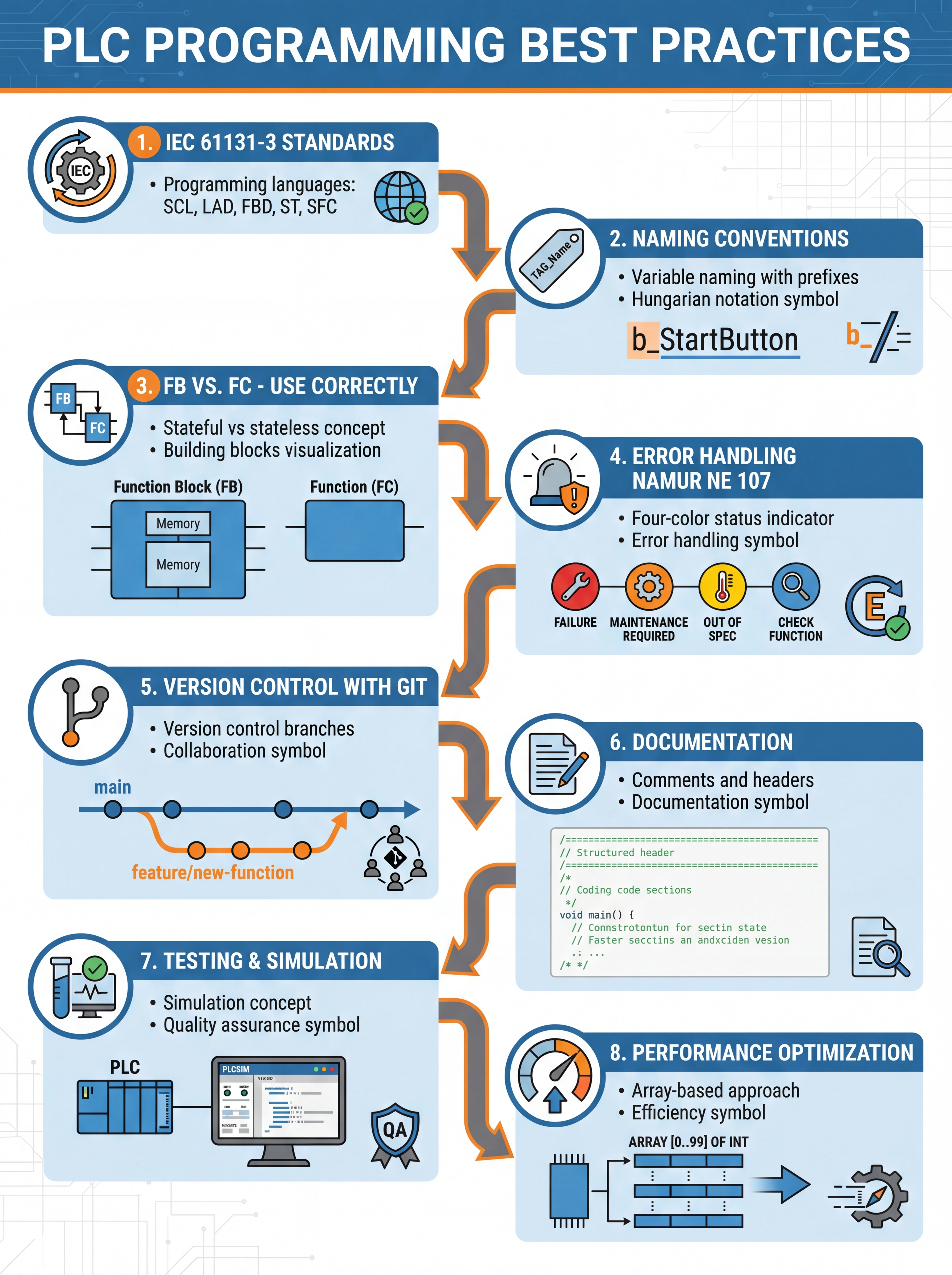

12.Infographic: PLC Best Practices at a Glance

13.Further Resources

- IEC 61131-3 Standard: PLCopen.org

- Siemens TIA Portal Best Practices: Siemens Support

- NAMUR NE 107: NAMUR.net

- Git for PLC: PlcGit Documentation

About the Author: David Prybisch has been working as a PLC programmer for over 10 years. He supports machine builders with structured programming using Siemens TIA Portal, code reviews, and commissioning.

Questions about your automation project?

As an automation engineer based in Stadtbredimus, Luxembourg, I offer free initial consultations for companies in the Greater Region Saar-Lor-Lux.

David Prybisch · PLC · HMI · Commissioning

Related Articles

WinCC Unified and React: Synergies for Modern HMI Development

WinCC Unified uses the Google V8 Engine. How automation engineers benefit from React skills: ES6 JavaScript and Custom Web Controls.

Read more: WinCC Unified and React: Synergies for Modern HMI Development

Automation in Luxembourg 2025: Trends Shaping the Greater Region

Six automation trends for the Saar-Lor-Lux region: AI integration, robotics boom, and how 335,000 missing workers are driving investments.

Read more: Automation in Luxembourg 2025: Trends Shaping the Greater Region

Worldwide Commissioning: A Field Report from 30+ Projects

Practical insights from international commissioning projects: From preparation through factory testing to final acceptance – with checklists and lessons learned.

Read more: Worldwide Commissioning: A Field Report from 30+ Projects